Think of an Amazon FBA prep service as the “backstage crew” for your e-commerce brand. They’re the specialists who handle all the essential labeling, bagging, and bundling that Amazon requires before your products can even hit their fulfillment network. They’re the partners who make sure your inventory meets Amazon’s notoriously strict rules, saving you from expensive rejections and painful delays.

Why FBA Prep Services Are a Seller’s Secret Weapon

Let’s imagine your Amazon business is a hit Broadway show. You’re the director, focused on the big picture—sourcing amazing products (the script), crafting killer marketing campaigns (promoting the show), and keeping the finances in order. But what about everything happening behind the curtain? Who’s making sure every prop is in the right place, correctly labeled, and ready for its big moment?

That backstage work? That’s exactly what an Amazon FBA prep service does. They are the invisible engine powering the tedious but absolutely critical tasks that Amazon demands before your inventory is allowed through the door of its fulfillment centers.

The Hidden Costs of DIY Prep

For a lot of sellers, especially when they’re just starting out, doing FBA prep yourself seems like a no-brainer. You buy a label printer, a giant roll of poly bags, and turn your garage into a mini-warehouse. It works for a while. But as your business scales, that DIY approach quickly turns into a massive bottleneck.

Every hour you spend printing FNSKU labels, bubble-wrapping fragile items, or building product bundles is an hour you aren’t spending on what actually moves the needle. You know, the high-value tasks that grow your business:

- Sourcing new products to expand your catalog and find your next winner.

- Optimizing your listings to boost conversion rates and climb the rankings.

- Running marketing campaigns to drive traffic and sales.

- Digging into the data to make smarter inventory buys.

Before you know it, you’re drowning in packing tape and cardboard boxes, working in your business instead of on it. Your growth grinds to a halt.

The High Stakes of Compliance Errors

It’s not just about the time you lose, either. It’s the very real risk of making mistakes. Amazon’s fulfillment network is a finely tuned machine built on perfect standardization. One tiny error—a label that’s slightly crooked, a poly bag that’s the wrong thickness, or a missing suffocation warning—can set off a chain reaction of problems.

A simple mistake in your prep can lead to rejected shipments, surprise fees, lost sales, and a hit to your account health. It can turn a potential bestseller into a logistical nightmare overnight.

Amazon has zero hesitation in penalizing sellers for non-compliant shipments. These penalties range from “unplanned service fees” (where Amazon fixes your mistakes and sends you a hefty bill) to having your entire shipment rejected and sent back on your dime. All the while, your products are out of stock, your sales rank is tanking, and your customers are getting frustrated.

A professional prep service is your insurance policy against all of this. They ensure every single unit meets Amazon’s ever-changing rules with precision. They turn prep from a major liability into a reliable, scalable part of your operation.

Understanding the Core FBA Prep Services

Diving into the world of Amazon FBA prep services is like getting a backstage pass to your own e-commerce operation. It’s the nitty-gritty, essential work that transforms a product from your supplier into a Prime-eligible item ready for Amazon’s massive fulfillment network. Each service is a crucial, deliberate step designed to meet Amazon’s notoriously strict standards.

Think of it like getting a race car ready for the track. You wouldn’t just fill it with gas and go. You’d check the tires, tune the engine, and make sure every single component is perfect. That’s exactly what FBA prep does for your products—it ensures they’re not just ready, but fully optimized for the journey to your customers.

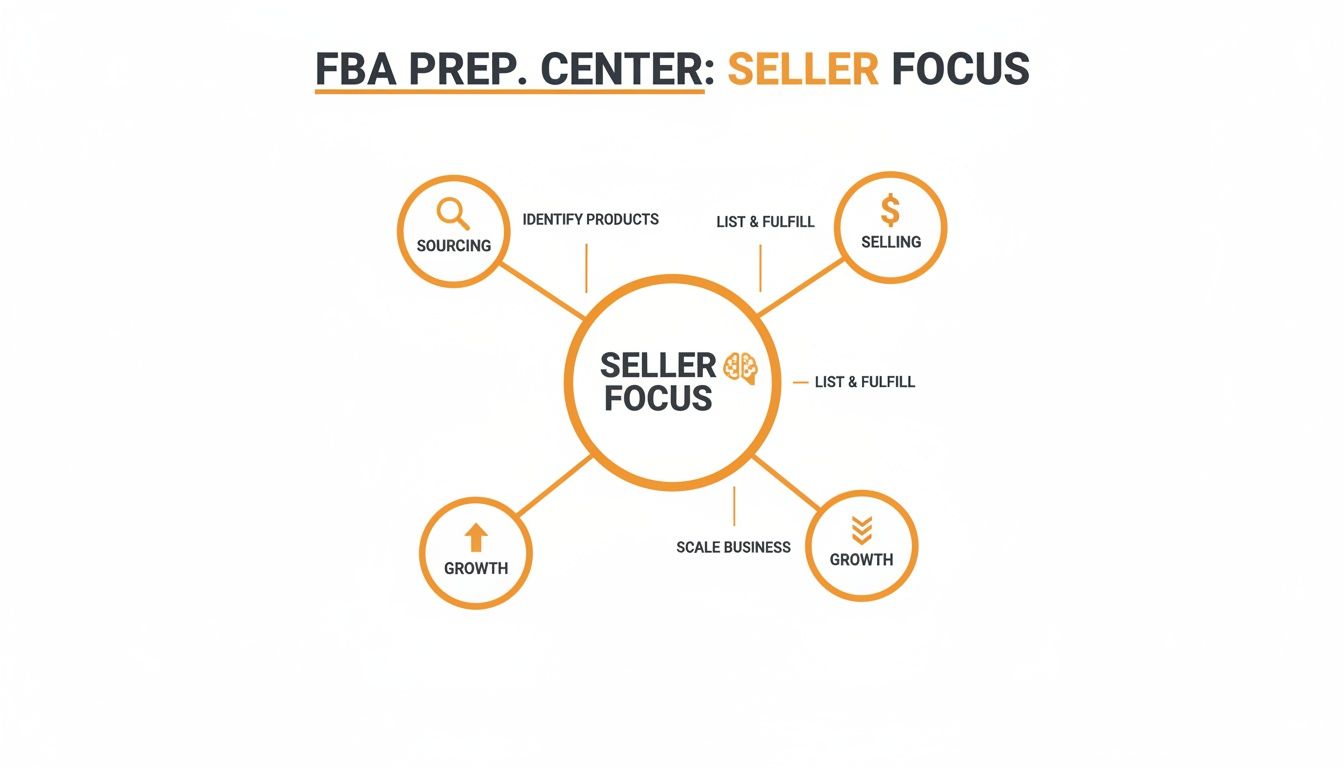

Handing this off means you can stop worrying about the operational weeds and start focusing on what really grows your business: sourcing, selling, and scaling.

As you can see, a prep center becomes the operational engine of your business, freeing you up to concentrate on the three pillars of e-commerce growth.

To give you a clearer picture, here’s a quick rundown of the most common prep services and why they are so critical for any serious Amazon seller.

| Service | What It Achieves | Problem It Solves |

|---|---|---|

| FNSKU Labeling | Assigns a unique Amazon ID to each product unit. | Prevents lost inventory, commingling, and incorrect payouts. |

| Poly-Bagging | Protects items from dust, moisture, and warehouse grime. | Stops products from arriving dirty or damaged. |

| Bubble Wrapping | Cushions fragile items against drops and impacts. | Avoids costly breakage and negative customer reviews. |

| Bundling & Kitting | Creates a new, high-value product from multiple items. | Increases average order value and creates unique listings. |

| Expiration Date Labeling | Clearly marks “best by” dates for Amazon’s system. | Ensures compliance for grocery, supplements, and beauty items. |

These services aren’t just busywork; they are your first line of defense against costly mistakes that can derail your FBA business. Let’s break down the most important ones.

FNSKU Labeling and Barcode Management

The absolute cornerstone of all FBA prep is FNSKU labeling. An FNSKU (Fulfillment Network Stock Keeping Unit) is your product’s unique fingerprint inside Amazon’s ecosystem. It’s a special barcode that ties a specific unit directly to your seller account, making sure you get credit when it sells. Simple as that.

Without a correct FNSKU, your product is basically an orphan. It might get mixed up with another seller’s lower-quality inventory (a commingling nightmare) or, even worse, get lost in a fulfillment center black hole. A prep service meticulously applies these labels to every single item, guaranteeing they scan perfectly and track accurately.

Pro Tip: Don’t think of FNSKU labeling as just another rule. It’s your official claim of ownership on every unit you send to Amazon. Getting this step right is the single most important thing you can do to protect your inventory and get paid.

For a deeper dive, check out our guide on how to prepare and label your products for FBA like a pro.

Protective Packaging: Poly-Bagging and Bubble Wrapping

Beyond labeling, protecting your products is everything. Amazon’s warehouses are fast-paced, industrial environments. Your items will get tossed around. This is where the right protective packaging makes all the difference.

- Poly-Bagging: This is mandatory for tons of products, from t-shirts to plush toys. A poly bag keeps items safe from dust, dirt, and moisture. Amazon has specific rules, too—the bag must have a certain thickness and a clear suffocation warning label if the opening is over 5 inches.

- Bubble Wrapping: For anything fragile—glass jars, ceramics, delicate electronics—bubble wrap is non-negotiable. A good prep center knows exactly how much padding an item needs to survive Amazon’s dreaded drop tests and prevent expensive breakage.

- Cap Sealing: If you sell liquids like supplements or cosmetics, you need to make sure the caps are securely taped or sealed. A single leak can damage a whole pallet of other sellers’ inventory, leading to hefty penalties for your account.

Bundling and Kitting for Higher Value

One of the smartest and most profitable services a prep center offers is bundling or kitting. This is where you combine several different products into a single, ready-to-sell unit. Think of creating a “Grill Master’s Kit” by packaging BBQ sauce, a set of tongs, and a meat thermometer together.

This strategy is a game-changer. It can dramatically increase your average order value and create a unique product listing that competitors can’t just copy. A prep center handles all the assembly, creates a new master package, and applies a single FNSKU label to the final bundle.

This service turns a few individual SKUs into a much higher-value product, all without you ever lifting a finger. It’s one of the best ways to stand out and boost your margins on the platform.

Mastering Amazon’s Strict FBA Compliance Rules

Amazon’s fulfillment network is a logistics marvel, a massive machine that moves millions of products every single day. To keep that machine humming, Amazon has a set of non-negotiable rules for every item that enters its fulfillment centers. Think of these FBA prep requirements less like guidelines and more like the hard-and-fast laws of their universe.

Every rule, no matter how small it seems, is there for a good reason. That suffocation warning on a poly bag isn’t just bureaucratic red tape; it’s a vital safety measure. The specific way they require you to tape liquid containers prevents a single leaky shampoo bottle from ruining an entire pallet of inventory—both yours and other sellers’. It’s all about maximizing warehouse efficiency, keeping employees safe, and making sure the customer gets a perfect product every time.

Breaking these rules comes with consequences that are both swift and expensive. It’s never a matter of if you’ll get caught, but when.

The High Cost of Non-Compliance

Ignoring or misinterpreting Amazon’s FBA rules is one of the quickest ways to watch your profits evaporate. The penalties aren’t just a slap on the wrist; they’re designed to be painful enough to ensure sellers get it right, protecting the integrity of the entire system.

When a shipment that isn’t compliant arrives at an Amazon facility, a few things can happen, and none of them are good for your business:

- Inventory Holds: Your products are pulled aside and stuck in a logistical purgatory while Amazon sorts out the problem. While this is happening, your listing shows “out of stock,” your sales rank tanks, and your competitors are more than happy to pick up your lost sales.

- Unplanned Prep Fees: Amazon’s team will fix your mistakes for you, but they’ll send you a hefty bill for their trouble. These “unplanned service fees” are significantly higher than what any third-party prep center would charge, cutting directly into your bottom line.

- Shipment Rejection: For more serious issues, Amazon will just refuse the entire shipment. It gets sent back to you at your expense, and then you have to pay to fix everything and pay to ship it all back in again. You just doubled your inbound shipping costs.

“One compliance mistake can cost you a month of lost sales. The penalties are swift, and the impact on your inventory availability and account health can be devastating.”

Ultimately, repeated problems can lead to the worst-case scenario: a suspension of your FBA privileges or even your seller account. In Amazon’s eyes, if you can’t follow the rules, you’re a risk to their operation.

Why a Prep Partner Is Your Compliance Insurance

This is exactly where professional amazon fba prep services are a game-changer. They do more than just pack boxes; they are your insurance policy against compliance headaches. A good prep partner lives and breathes Amazon’s constantly changing rulebook. Their entire business is built on mastering these details so you don’t have to.

They’re experts in the little things that trip up most sellers:

- Label Placement: Making sure FNSKU labels are perfectly placed, fully covering old barcodes, and scannable every time.

- Material Specs: Knowing the exact thickness required for poly bags or the right kind of dunnage for fragile items.

- Expiration Dates: Applying date labels in the precise format and font size Amazon demands for grocery or beauty products.

A dedicated prep partner follows every update in Seller Central, so they see changes coming and make sure your inventory is always compliant. For sellers trying to keep up, especially with major updates like Amazon’s new packaging and prep guidelines for 2025, a prep partner isn’t a luxury. It’s a critical part of building a scalable and resilient e-commerce business, shielding you from the financial drain of compliance issues so you can focus on growing your brand.

The Strategic Payoff of Outsourcing FBA Prep

It’s easy to look at Amazon FBA prep services as just another cost on your P&L sheet, but that completely misses the point. You’re not just paying someone to stick labels on boxes. You’re making a strategic choice to shift your role from a warehouse packer to a brand builder—and that’s a powerful lever for growth.

Think about the classic seller story: spending 15-20 hours every single week drowning in bubble wrap, inventory counts, and FNSKU labels. That’s nearly half a workweek spent on tedious tasks that don’t actually make you money. Handing this work off doesn’t just buy you time; it buys you opportunity. You get those hours back to focus on what matters—product research, marketing, and staying ahead of your competition.

It’s the difference between working in your business and working on it. You turn an operational bottleneck into a launchpad for your next big move.

Slashing Overhead and Gaining Financial Flexibility

One of the first things you’ll notice is the complete disappearance of physical infrastructure costs. Setting up your own prep operation is a huge capital investment. You need warehouse space, shelving, packing stations, label printers, and a never-ending supply of materials.

More importantly, you need people. Hiring, training, and managing staff comes with payroll, insurance, and administrative headaches. By partnering with a prep center, you sidestep all of it.

You get immediate access to a fully equipped, professionally staffed warehouse without spending a dime on rent, equipment, or employee benefits. This flips a massive fixed cost into a predictable, variable expense that scales directly with your sales.

This model is just plain smarter. During slow months, your prep costs are minimal. When sales explode during Q4, you don’t have to scramble to hire temps; your partner simply handles the surge.

Achieving Instant and Effortless Scalability

Seasonal peaks and surprise sales spikes are a nightmare when you’re handling your own prep. One good marketing campaign can turn your garage into an impassable maze of boxes, creating a massive shipping logjam that kills your momentum.

An FBA prep service gives you scalability on demand. Their entire operation is built to handle fluctuating volumes from hundreds of clients. Your Q4 rush is just another Tuesday for them.

This operational elasticity gives you a few key advantages:

- Conquer Peak Seasons: Attack major sales holidays like Black Friday with total confidence, knowing your logistics can handle a 10x increase in order volume without a hiccup.

- Launch Products Faster: Send huge initial inventory orders straight from your supplier to your prep partner, getting new products live on Amazon faster to capture those crucial early sales.

- Pursue Bigger Deals: Say “yes” to wholesale opportunities or large B2B orders that would have otherwise buried your in-house capacity.

Leveraging Specialized Expertise to Prevent Costly Errors

Finally, a dedicated prep partner brings deep expertise to the table. These guys live and breathe Amazon’s complex and constantly changing compliance rules. As FBA grows, so does its complexity. In 2025, an estimated 82% of Amazon’s 2.5 million active sellers used FBA, creating a massive, competitive ecosystem where getting the details right is everything. With 58% of FBA sellers hitting profitability in their first year, having your logistics dialed in is a clear advantage, especially as Amazon’s fees continue to climb. You can find more FBA seller statistics on redstagfulfillment.com.

This expertise is your shield against expensive mistakes. A single compliance error can lead to rejected shipments, surprise fees, and weeks of lost sales while your inventory sits in limbo. A professional prep team makes sure every label is perfect, every poly bag has the right warning, and every bundle is secure—safeguarding your revenue and your account health.

How to Choose the Right FBA Prep Partner

Picking an FBA prep partner is a lot like hiring a new team member. The right one becomes an invisible, invaluable part of your operations, making sure your inventory flows into Amazon without a hitch. But the wrong one? They can create costly delays, compliance headaches, and logistical nightmares you’ll be stuck fixing.

Your goal isn’t just to find a vendor who slaps labels on boxes. You need a real partner who gets your business, communicates clearly, and can keep up as you grow. It all starts with asking the right questions and knowing what to look for in their answers.

Evaluating Key Service Metrics

Before you even jump on a call, you should have a mental checklist of your non-negotiables. A professional amazon fba prep services provider will be upfront and transparent about these core metrics.

Here’s what you absolutely need to nail down:

- Guaranteed Turnaround Times: How fast can they get your inventory received, prepped, and ready for an Amazon truck? A solid partner should promise a 24-72 hour turnaround. Anything more than that, and you risk going out of stock.

- Transparent Pricing Structure: Vague pricing is a major red flag. Ask for a detailed price list that breaks down the cost for every single service—labeling, poly-bagging, bundling, even the materials they use. Keep an eye out for sneaky fees for things like receiving, storage, or account management.

- Strategic Location: Where are their warehouses? A prep center located near major coastal ports or Amazon’s key fulfillment centers can drastically cut down your inbound shipping costs and speed up transit times.

- Software and Integration: What system do they use to manage your inventory? You want a partner with a modern software platform that gives you a real-time window into your stock and, ideally, integrates directly with your Seller Central account.

Asking the Right Questions

Once a potential partner ticks all the basic boxes, it’s time to dig deeper. The answers to these questions will show you how they really operate, especially when things don’t go according to plan.

A great prep partner doesn’t just promise perfection; they have clear, proven processes for handling imperfection. Their ability to manage exceptions—like damaged goods from a supplier or an unexpected inbound delay—is what separates the professionals from the amateurs.

Show up to that first meeting ready with a few pointed, scenario-based questions:

- Communication on Inbound Issues: “What’s your exact process if a shipment from my supplier shows up with crushed boxes or the wrong number of units?” A good answer involves immediate photo proof, email alerts, and a clear protocol for what happens next.

- Handling Damaged Goods: “If you find damaged products during your inspection, what are my options? Can you dispose of them, ship them back to my supplier, or just set them aside for me?” You’re looking for flexibility here.

- Managing Amazon Compliance Errors: “Let’s say Amazon flags a shipment you prepped for a compliance issue. How do you investigate and fix it? Do you take any responsibility?” This question cuts right to their level of accountability.

- Scaling for Peak Season: “How do you handle the Q4 rush? What guarantee do I have that my turnaround times won’t double during the holidays?” They need a solid plan for hiring seasonal staff and scaling their operations.

By focusing on these practical details, you can confidently choose a partner who will truly support your growth. To learn more about how a 3PL can streamline this process, explore our complete guide to using a 3PL for Amazon FBA prep.

Partnering with Snappycrate to Scale Your Brand

Choosing the right amazon fba prep services provider isn’t just about finding a warehouse. It’s about finding a team that gets what’s really on the line—your inventory, your cash flow, and the reputation you’ve worked so hard to build.

At Snappycrate, we get it because we’re e-commerce sellers, too. We’ve lived the late nights and frustrating logistics puzzles that come with scaling a brand. We built our services from the ground up to solve the real problems that keep sellers like you from growing.

This isn’t just a list of services; it’s our commitment to being a true operational partner. We look past the individual boxes and labels to see how flawless prep and fulfillment can fuel your bigger vision.

Differentiators That Drive Real Growth

We’ve built our entire operation around solving the biggest headaches for growing brands. These aren’t just add-ons; they’re core capabilities designed to give you a serious competitive edge.

-

Full Container Processing: Sourcing directly from overseas is a huge milestone. We’re fully equipped to receive and process your 20-foot or 40-foot containers, breaking them down and prepping everything for FBA. You can skip the hassle and expense of finding a separate cross-docking facility.

-

Multi-Channel Fulfillment: Your brand doesn’t live only on Amazon, and neither do we. We offer seamless fulfillment for your Shopify and Walmart stores, managing all your inventory from one unified hub. Simple.

-

Custom Brand Experiences: We help your brand pop with custom packaging, kitting, and branded inserts. It’s all about creating that memorable unboxing experience that turns a one-time buyer into a loyal fan.

This holistic approach means we can support your brand’s journey from its first pallet to its first full container, and across every sales channel you add along the way.

A Partnership Proven by Results

The real measure of a great partnership is in the results. Just ask our clients.

One of our partners was getting hammered by inbound compliance errors, leading to costly delays and chargebacks from Amazon. After they made the switch to Snappycrate, they hit 100% error-free FBA shipments. Those fees vanished, and their inventory check-in times got a whole lot faster.

Another client was staring down a chaotic Q4, terrified their old provider couldn’t handle the holiday rush. We stepped in and helped them triple their order volume during the peak season without a single hiccup. They captured every possible sale.

Your prep partner shouldn’t just be a defensive measure to prevent problems. They should be an offensive asset that actively enables growth. The right partnership transforms your supply chain from a potential headache into a powerful tool for scaling your brand.

With major industry shifts coming, having a reliable partner is more critical than ever. Amazon just announced they are ending their own FBA prep services on January 1, 2026. This move is about to send over 400,000 sellers scrambling for new solutions. By getting a proven, growth-focused partner like Snappycrate in your corner now, you’re not just getting ahead of the curve—you’re securing a massive strategic advantage. You can read more about this industry shift at zimark.io.

Got Questions? We’ve Got Answers

Stepping into the world of FBA prep services can bring up a few questions. We get it. Here are the straight-up answers to the most common things sellers ask before they hand over this crucial piece of their business.

How Much Do FBA Prep Services Actually Cost?

Most prep centers work on a “per-touch” pricing model, which usually lands somewhere between $0.50 and $2.00 per item. A simple job, like slapping an FNSKU label on a product, is going to be on the low end of that range.

The price starts to climb when you need more complex work. Think about things like:

- Creating product bundles or multi-packs

- Bubble wrapping fragile items

- Adding special inserts or marketing materials

Before you commit, always ask for a complete pricing sheet that breaks down every possible fee, like receiving, short-term storage, or the cost of materials. A good partner will give you a clear, all-in quote based on what you actually need.

Here’s a solid rule of thumb: every single time a worker has to physically handle or “touch” your product to do something, it adds to the cost. That’s why a simple label is always cheaper than building a multi-item bundle.

What’s a Realistic Turnaround Time?

You should expect a turnaround time of 24 to 72 hours. That clock officially starts ticking the moment your inventory hits the prep center’s loading dock and stops when it’s fully prepped and waiting for an Amazon-partnered carrier to pick it up.

Of course, this can shift depending on how complex your prep job is and the sheer size of your shipment. It’s super important to confirm the service level agreement (SLA) with your provider upfront. A partner you can count on will be transparent about their current processing times so there are no surprises.

Can I Use a Prep Center if I Source Products Internationally?

Absolutely. In fact, this is one of the biggest strategic moves you can make as a seller. Many brands ship products directly from their manufacturer in China or elsewhere straight to a US-based prep center like ours. We then become your team on the ground, handling everything from quality checks to making sure every last box is FBA-compliant.

This single move can save you a massive amount of time and money. You get to skip the incredibly expensive and slow step of shipping everything to your own office, only to turn around and send it right back out to Amazon’s warehouses. It’s a game-changer for streamlining a global supply chain.

Ready to stop wrestling with prep work and start focusing on growing your brand? The team at Snappycrate has the experience and the setup to scale right alongside you. See how our FBA prep services can make your operations run smoother.