Let's be honest, "logistics" is one of those words that sounds complicated and expensive. But a 3PL (Third-Party Logistics) warehouse is actually pretty simple: it's your outsourced operations partner. Think of them as the team that handles all the physical stuff—storing your products, packing your orders, and shipping them out—so you don't have to.

Your Business Command Center, Not Your Garage

Every successful e-commerce brand reaches a point where the garage, spare bedroom, or basement is overflowing with inventory. That's the moment you graduate to a professional command center that runs your fulfillment on autopilot.

That’s what a 3PL warehouse really is. It’s not just a storage unit; it's an active, integrated partner that plugs into your online store and manages the entire journey of your product, from the moment it arrives at their dock to the second it lands on your customer's doorstep. This frees you up to focus on what actually grows your brand: marketing, product development, and customer relationships. No more printing labels and wrestling with packing tape.

And you wouldn't be alone. More and more businesses are turning to logistics experts to stay competitive. The Third-Party Logistics industry in the United States now includes over 72,000 businesses, with revenues expected to hit a massive $138.4 billion in 2025. This isn't just a trend; it's a fundamental shift in how modern e-commerce brands operate. You can see more data on this growth at Grandviewresearch.com.

Core Functions of a 3PL Warehouse at a Glance

So, what does a 3PL warehouse actually do day-to-day? While every partner is different, their work boils down to a few core services that solve the biggest headaches for online sellers.

This table breaks down the three main pillars of 3PL services and what they mean for your business in practical terms.

| Core Service | What It Means for Your Business | Key Benefit |

|---|---|---|

| Warehousing | Securely storing your inventory in an organized, professional facility. | Frees up your personal space and ensures products are safe and accounted for. |

| Inventory Management | Using software to track stock levels in real time, preventing overselling. | Maintains accurate counts and provides the data you need for restocking. |

| Pick, Pack, & Ship | Fulfilling customer orders by picking items, packing them, and shipping them out. | Achieves faster shipping times and higher order accuracy without your effort. |

Ultimately, the right 3PL warehouse acts as a true extension of your own team. They bring the infrastructure, technology, and expertise you need to scale your operations without the massive upfront investment.

By understanding these core functions, you can start to see how a 3PL can directly support your business goals. For a deeper dive into scaling your business, you might be interested in our guide on getting started.

The Journey of a Product Inside a 3PL

To really get what a 3PL warehouse does, let’s follow one of your products from the moment it hits our dock. Thinking about it this way pulls back the curtain on the whole fulfillment process, turning an abstract idea into the concrete steps we take every single day for e-commerce brands just like yours.

The journey starts the second your inventory arrives at our loading dock. This could be a handful of boxes you shipped over or a full-on shipping container straight from your supplier. We call this first step inbound receiving.

Our team gets to work unloading the shipment, checking that everything matches the list you sent us—no surprises. Each product gets a quick inspection for damage before it's scanned into our Warehouse Management System (WMS). Just like that, it’s officially part of your on-hand inventory, ready to be sold.

Strategic Storage and Smart Placement

Once your products are checked in, they don’t just get tossed onto a random shelf. This isn't your garage. The WMS assigns every single item a specific home—a bin, a shelf spot, or a pallet rack location.

And there’s a method to the madness. Your best-sellers? We keep those in easy-to-reach spots to make picking them for orders super fast. Slower-moving items might go a bit higher up or further back. It’s all about organized chaos, designed for maximum efficiency and accuracy.

The Order Fulfillment Cycle

This is where the real action begins. A customer clicks "buy" on your Shopify or Amazon store, and that order zips right into our system automatically. That single click kicks off a finely tuned workflow:

Order Picking: A warehouse team member gets a "pick list" on their handheld scanner. The device maps out the fastest route through the warehouse to grab everything for an order. They scan each item as they go to ensure 100% accuracy.

Order Packing: The items are whisked over to a packing station. Here, a packer finds the perfect-sized box, adds any needed dunnage (like bubble wrap), tucks in any marketing inserts you’ve sent us, and seals it all up.

Shipping: The sealed box hits the scale, and our system spits out the right shipping label based on what the customer selected at checkout. From there, it joins a sea of other packages, all ready for carriers like UPS, FedEx, or USPS to scoop them up.

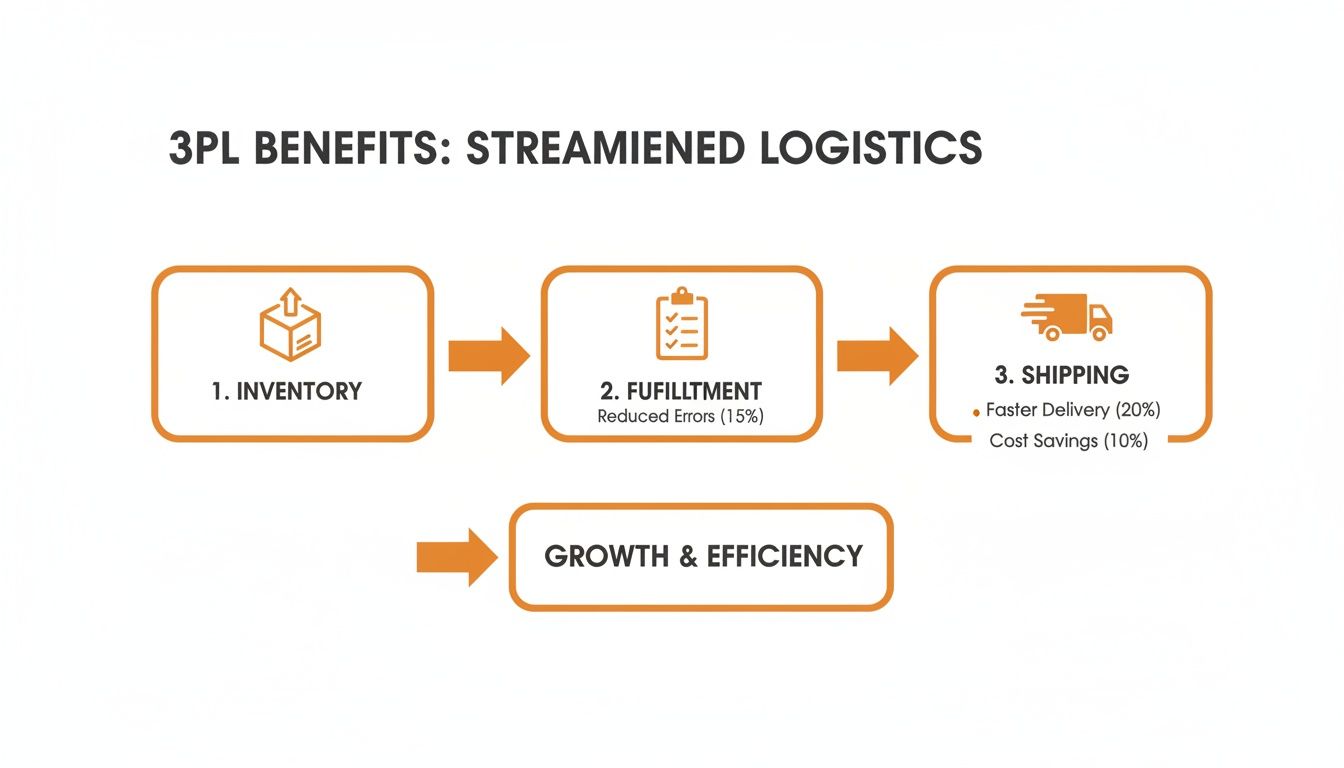

This infographic breaks down how all these moving parts—inventory, fulfillment, and shipping—come together in one smooth operation.

As you can see, a good 3PL partner turns what feels like a logistical nightmare into a simple, straightforward process. It frees you up to actually focus on growing your business.

The second the carrier picks up that package, tracking info is automatically pushed to your store and sent to your customer. The journey is complete, and another happy customer is about to get their order.

Core Services That Fuel E-Commerce Growth

Sure, warehousing and shipping are the basics. But the real magic of a 3PL warehouse isn't just storing boxes—it's the specialized services that help e-commerce brands actually grow. These aren't just fluffy add-ons; they're strategic tools that boost your efficiency, wow your customers, and keep you compliant with giants like Amazon.

Think of these services as the high-performance parts that turn a standard fulfillment operation into a growth engine.

At the center of it all is a powerful tech backbone. Modern 3PLs run on sophisticated software that gives you a live look into your inventory and orders. This isn't a minor upgrade; it's a fundamental shift. Today, 86% of 3PLs rely on a Warehouse Management System (WMS) to run the show. Why? 87% want real-time inventory tracking, and 75% are laser-focused on making their operations more efficient. You can see more on how tech is changing the game in this detailed 3PL statistics report.

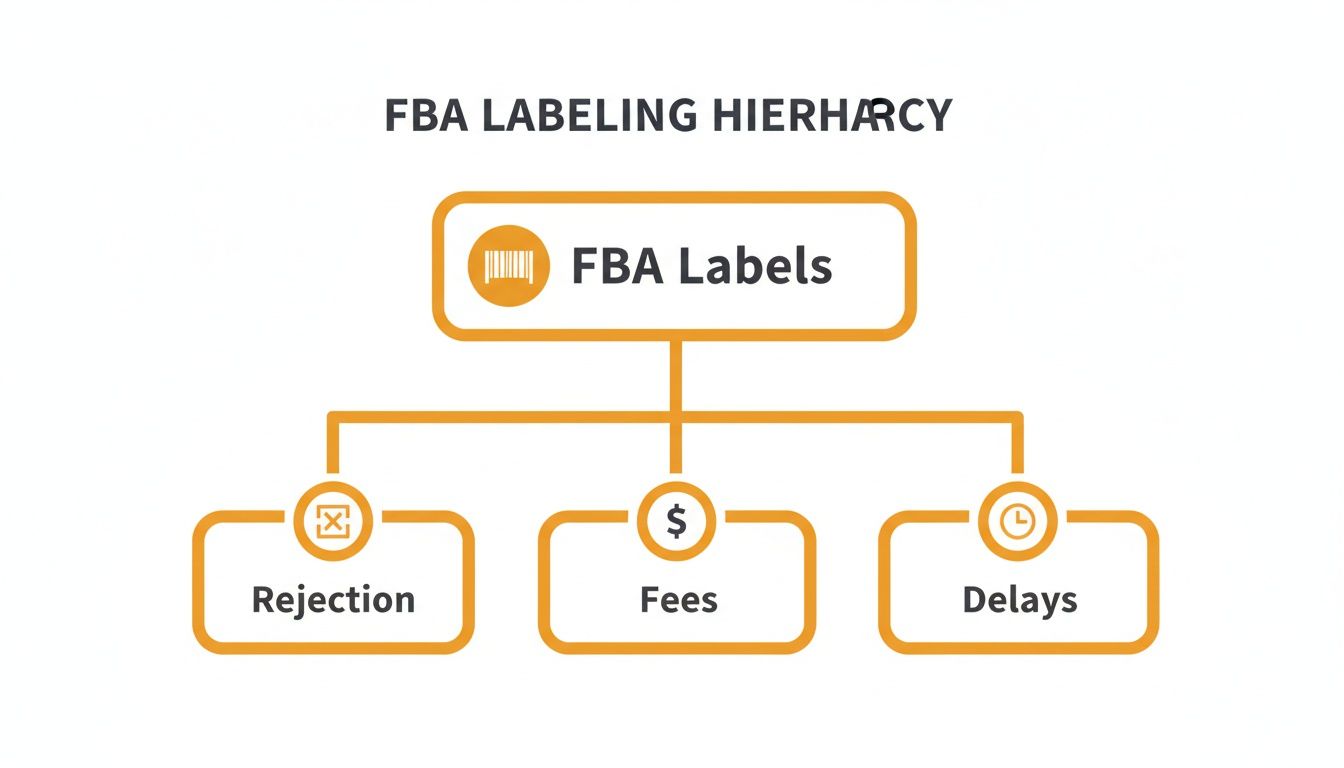

Essential FBA Prep and Compliance Services

Selling on Amazon FBA is a massive opportunity, but let's be honest—it comes with a notoriously strict rulebook. One small mistake in prepping your inventory can lead to rejected shipments, frustrating penalties, and lost sales. This is where a 3PL that knows Amazon inside and out becomes your most valuable partner.

A good 3PL handles all the nitpicky tasks to make sure every shipment sails through Amazon's receiving docks.

- FNSKU Labeling: Amazon uses its own FNSKU barcodes to track every item. Your 3PL will label each unit perfectly, covering any old manufacturer barcodes to prevent scanning errors that can wreak havoc on your inventory.

- Poly Bagging: Got apparel, plush toys, or items that could get dusty? They need to be in a poly bag, often with a specific suffocation warning. A 3PL knows the rules and gets it done right.

- Bundling and Multipacks: If you sell a shampoo and conditioner combo, your 3PL will physically bundle them and slap on a "Sold as a Set" label. This tells Amazon's warehouse team not to split them up.

Outsourcing these tedious tasks saves you from the headache of keeping up with Amazon’s constantly changing requirements. You can dive deeper into this process in our guide on Amazon FBA prep services.

Value-Added Services That Build Your Brand

Beyond just following the rules, the right 3PL partner can help you build your brand identity. These value-added services are all about creating a memorable customer experience that makes you stand out.

A memorable unboxing experience can turn a one-time buyer into a loyal customer. It’s often the first physical interaction a customer has with your brand, making it a powerful marketing opportunity.

Kitting is a perfect example. This is where a 3PL assembles multiple separate items into a single package, like a subscription box or a holiday gift set. It lets you create brand-new product offerings without touching your manufacturing process.

Plus, a 3PL can use your custom branded boxes, tissue paper, and thank-you cards to create an unboxing experience that screams quality and shows off your brand’s unique personality.

Understanding the Real ROI of a 3PL Partnership

Calculating the true value of a 3PL warehouse isn't about comparing your current costs to their monthly invoice. The real return on investment isn't just saving a few bucks on rent or shipping labels—it’s about buying back your most valuable asset: your time.

Think about the daily grind of running an e-commerce brand from your garage. You lose hours receiving inventory, fighting with packing tape, and making runs to the post office. This isn’t just inefficient; it’s a massive bottleneck. Every hour spent on logistics is an hour you can't spend on marketing, product development, or customer service—the things that actually grow your business.

From Direct Savings to Strategic Growth

The most obvious ROI comes from ditching direct operational costs. You get to eliminate a warehouse lease, payroll for pickers and packers, and big investments in equipment like forklifts and shelving. This frees up a ton of capital that you can pump right back into more inventory or a new marketing campaign.

But the real magic happens with the operational efficiencies a 3PL brings to the table.

- Reduced Shipping Costs: 3PLs ship in huge volumes, which gives them access to heavily discounted carrier rates that a small business could never get on its own.

- Fewer Errors: Professional fulfillment centers have processes that minimize costly mistakes, like sending the wrong item or shipping to an old address. This protects both your profits and your brand’s reputation.

- Faster Fulfillment: With optimized workflows and a dedicated team, a 3PL gets orders out the door much faster, leading to happier customers and better reviews.

The Ultimate Return: Time and Scalability

This shift from DIY fulfillment to a professional partnership is where you unlock true scalability. And market conditions are making it easier than ever. The national warehouse vacancy rate recently hit 7.1%, its highest point since 2014, meaning there’s more space available for growing brands. This is a big reason why 87% of shippers increased their use of outsourced logistics in 2025—a 25% jump from the year before. You can dig into more of this data in a recent report on industrial leasing.

By outsourcing logistics, you aren't just offloading tasks; you are investing in a system designed for growth. It allows you to focus on strategic initiatives while your fulfillment engine runs seamlessly in the background.

Ultimately, partnering with a 3PL warehouse transforms your daily workflow from reactive to proactive. You stop putting out fires and start building your brand. That shift doesn’t just improve your bottom line—it gives you the freedom to lead.

How to Choose the Right 3PL Warehouse

Picking a fulfillment partner is one of the biggest moves you’ll make for your e-commerce brand. This isn't just about renting some shelf space; you're handing over a huge piece of your customer experience to an outside team. Get it right, and a 3PL can be the engine for massive growth. Get it wrong, and you're in for a world of logistical nightmares and angry customers.

To make a smart choice, you need to look past the price sheets. It’s all about finding a partner whose tech, skills, and culture line up with where your brand is now—and where you plan on taking it.

Technology and Integrations

Think of your 3PL as a technology partner first, a warehouse second. Their ability to plug directly into your e-commerce store is absolutely non-negotiable. If their systems can’t talk to yours, you’ll find yourself manually keying in orders, which completely defeats the purpose of outsourcing in the first place.

Before you even think about signing a contract, insist on a live demo of their software. You need to see exactly how it works and confirm they have solid, ready-to-go integrations for your tech stack.

- E-commerce Platforms: Can they connect directly to your Shopify, BigCommerce, or whatever platform you use to sell?

- Marketplaces: Does their system automatically pull in orders from Amazon, Walmart, or other channels you rely on?

- Inventory Sync: How quickly does their system update your store’s stock levels? Real-time syncing is critical to prevent overselling.

A modern tech stack is what keeps the data flowing, ensuring your operations are accurate and efficient without you having to lift a finger.

A 3PL’s technology is the central nervous system of your fulfillment operation. Without seamless integration, you're creating more problems than you solve. A modern warehouse runs on data, not just forklifts.

Specialization and Expertise

Let’s be clear: not all 3PLs are the same. Some are pros at handling tiny, lightweight items, while others are built to move heavy freight. Finding a partner who actually gets your product category is key to making sure everything is handled correctly and stays compliant.

For instance, a 3PL that focuses on apparel will know all about poly bagging, SKU management for different sizes and colors, and returns processing. On the other hand, a partner who works with supplements will be an expert in lot tracking and managing expiration dates.

And if you sell on Amazon, their FBA prep expertise is make-or-break. Navigating Amazon's increasing non-compliant fees is a full-time job, and you need a partner who knows Amazon's rulebook backward and forward.

Scalability and Growth Potential

Finally, you have to think about the future. The 3PL that’s a perfect fit today might be a bottleneck in two years when your order volume explodes. You need a partner who can grow with you, not hold you back.

Don’t be shy about asking direct questions about their capacity and plans for expansion:

- What’s their typical daily order volume, and what’s their absolute max capacity?

- Do they operate multiple warehouses? This can be a game-changer for reducing shipping times and costs as you expand.

- How do they handle crunch time during seasonal peaks like Black Friday?

Choosing a 3PL with a clear path for growth means your fulfillment will always be a strength, not a weakness, as your business takes off.

Common Questions About 3PL Warehouses

Jumping into the world of fulfillment always brings up a few questions. To help you get clear, we’ve put together answers to some of the most common things business owners ask when they’re thinking about bringing on a 3PL partner.

How Much Does a 3PL Warehouse Cost?

There's no single price tag for 3PL services—and that's a good thing. Pricing is almost always tailored to your specific needs, so you only pay for what you actually use. Think of it less like a fixed monthly rent and more like a pay-as-you-go utility for your entire logistics operation.

Most pricing models are broken down into these core activities:

- Receiving: This is a one-time fee for getting your inventory in the door, which includes inspecting it and putting it away. It's often charged by the pallet, by the hour, or per unit.

- Storage: A recurring monthly fee for the physical space your products take up. This is usually calculated by the pallet, by the bin, or by cubic footage.

- Pick and Pack: A fee for every order we fulfill. This might be a flat rate per order or a smaller fee for each item we have to pick to complete an order.

- Shipping: This is the actual postage cost, which is passed through to you. One of the biggest perks here is that 3PLs get massive discounts from carriers due to their high shipping volumes, and those savings get passed on.

Since the final cost really depends on your order volume, product size, and any special handling needs, it’s always best to get a detailed quote.

When Is the Right Time to Switch to a 3PL?

Knowing when to hand over fulfillment can feel like a big decision, but there are usually some pretty clear signs that you've outgrown your current system. The real tipping point is when managing logistics starts taking up more of your time than actually growing the business.

Here are a few practical benchmarks that tell you it might be time to outsource:

- You're consistently shipping over 100 orders per month and feel like you’re barely keeping your head above water.

- You’re spending more than 10-15 hours a week just packing boxes instead of working on marketing, product development, or customer relationships.

- You’ve officially run out of space in your garage, office, or that storage unit you rented.

- Your order accuracy is starting to slip, which means more customer service headaches and costly returns.

Making the switch isn’t just about getting bigger; it’s about working smarter. Outsourcing fulfillment gives you back your time so you can focus on the strategic work that will actually scale your brand.

Can a 3PL Handle Both Amazon FBA and FBM?

Absolutely. In fact, finding a 3PL that truly understands the Amazon ecosystem is a massive strategic advantage. They can act as a flexible hub, managing your inventory and fulfilling orders for both FBA (Fulfillment by Amazon) and FBM (Fulfillment by Merchant) seamlessly.

For Amazon FBA, the 3PL serves as your prep center. They handle all the mission-critical compliance tasks—like applying FNSKU labels, poly bagging items, and creating bundles—to meet Amazon’s notoriously strict inbound requirements. This is your insurance policy against rejected shipments.

For Amazon FBM, the 3PL simply fulfills orders directly from their warehouse to your customer. This gives you far more control over your inventory and can often be a more profitable route for certain products. Using one 3PL for both lets you build a powerful, multi-channel fulfillment strategy without the logistical nightmare.

Ready to stop packing boxes and start scaling your business? Snappycrate is an e-commerce 3PL that acts as a true extension of your team, handling everything from storage and FBA prep to fast, accurate order fulfillment. Discover how we can streamline your operations by visiting us at https://www.snappycrate.com.