In logistics, kitting is the simple act of bundling multiple, separate items into a single ready-to-ship package or 'kit'. This new package gets its own unique SKU, turning what could have been a complex, multi-item order into a straightforward, single-unit fulfillment job.

What Kitting Really Means for Your Warehouse

Think of it like a meal-prep service for your fulfillment center. Instead of your team running all over the warehouse to grab ten different items for a single order, they just grab one pre-assembled box that already has everything inside.

It’s a simple shift in thinking, but it’s the foundation of what makes kitting such a powerful strategy. You’re doing the work upfront to make the final pick-and-pack process incredibly fast and almost error-proof.

The Core Idea: From Many SKUs to Just One

At its heart, kitting is all about simplification. You start with a collection of individual products, each with its own Stock Keeping Unit (SKU). These items are then combined to create a brand-new product—the kit—which gets its own master SKU.

This conversion from many SKUs to one has an immediate impact:

- Faster Picking: Warehouse staff aren't hunting for individual components anymore. They just find and pick the one master SKU.

- Quicker Packing: Since all the items are already gathered, packing becomes a fast, standardized step instead of a complicated assembly project at the pack station.

- Simpler Inventory: You’re no longer tracking dozens of small parts for your most popular bundles. Instead, you're primarily managing the stock of the finished kits.

Kitting flips the script on fulfillment. Instead of reacting to orders one item at a time, you’re proactively building ready-to-go packages. Preparing orders before they’re even placed is how you dramatically shrink the time from click to ship.

This approach is a direct solution to some of the biggest headaches in e-commerce fulfillment. A recent survey showed that 40% of e-commerce businesses were slowed down by order picking, while 37% struggled with inventory management.

To give you a clearer picture, let's break down the essential components of kitting.

Kitting at a Glance: Key Concepts Explained

This table simplifies the core elements of kitting and why they matter for your operations.

| Component | Description | Primary Benefit |

|---|---|---|

| Component SKUs | The individual items or products that will be included in the final kit. | Allows for precise tracking of raw inventory before assembly. |

| Bill of Materials (BOM) | The "recipe" for the kit, specifying which components and how many of each go into one finished package. | Ensures consistency and accuracy for every kit that's built. |

| Master SKU | The new, single SKU assigned to the finished, pre-assembled kit. | Drastically simplifies the picking process down to a single scan. |

| Kitting Workstation | A dedicated area in the warehouse where staff assemble the component SKUs into finished kits. | Creates an efficient, assembly-line workflow for building kits. |

By pre-assembling these bundles, you turn potential chaos into streamlined efficiency. It’s a foundational step that sets you up for major wins across your entire supply chain. As your business grows, exploring professional kitting and assembly services can give you a serious competitive edge without adding complexity to your own operation.

The Strategic Benefits of Kitting Services

Thinking about kitting as just a way to organize your warehouse is selling it short. It’s a direct investment in a smoother, more profitable operation. When you bundle individual items into a single, ready-to-ship unit, you trigger a chain reaction of benefits that touches everything from your shipping budget to your customer reviews.

At its core, kitting turns a complex, multi-item order into a simple grab-and-go task. That small shift has a massive impact on your speed, accuracy, and bottom line.

Drastically Reduce Shipping Costs

This is where you’ll see the first and most obvious win. Picking individual items often means they end up rattling around in a box that’s way too big, stuffed with void fill. Carriers don't just charge for weight; they charge for space. It's called dimensional (DIM) weight, and it can kill your margins.

Kitting flips the script. You can design custom packaging that fits your bundle perfectly. No wasted space means a smaller box, which means lower shipping costs on every single order.

The savings here aren't trivial. Businesses can cut their shipping spend by 15-30% just by eliminating oversized boxes and the DIM weight fees that come with them. As parcel rates keep climbing, that’s a huge competitive edge. For Amazon sellers, getting packaging right also means avoiding costly FBA rejection fees. Want to dig deeper into the numbers? You can discover more insights about warehouse kitting on dvunified.com.

Boost Order Accuracy and Customer Satisfaction

Fulfillment mistakes are expensive. A single mis-picked item doesn’t just cost you the return shipping; it costs you a replacement shipment and, worst of all, a customer who might never buy from you again. Kitting is your best defense against human error.

Kits are typically assembled in a dedicated area, often in large batches where quality control is the main focus. It's a much more controlled environment than the chaotic rush of picking and packing live orders.

By the time a picker grabs a kit from the shelf, the hard part is already done and double-checked. This simple change nearly eliminates the risk of sending out an incomplete or wrong order, which is a direct win for the customer experience.

When customers get exactly what they ordered, every time, they trust your brand. That trust turns into great reviews, repeat business, and a solid reputation.

Simplify SKU and Inventory Management

Trying to manage inventory for hundreds—or thousands—of tiny individual components is an operational nightmare. It makes forecasting a guessing game and increases the chances that a single out-of-stock part can bring your sales to a halt.

Kitting cleans up this mess by rolling up multiple component SKUs into one single "master" SKU for the finished kit. Instead of tracking ten different widgets, your warehouse team and your WMS only have to track one thing: the complete kit.

This consolidation leads to some major improvements:

- Easier Forecasting: It's much simpler to predict demand for one finished product than for all its individual pieces.

- Less Complex Picking: Your pickers grab one box from one location instead of running all over the warehouse for ten different parts.

- Smarter Warehouse Layout: Ready-to-ship kits can be stored in prime, forward-picking locations, while the bulk components can be tucked away in backstock.

This streamlined system means less time spent counting inventory and more time spent shipping orders. It's how you scale your business without getting buried in logistical complexity.

Digging into the Different Kitting Workflows

Not all kits are created equal, and how you assemble them can make or break your operational efficiency. It's crucial to understand the different kitting workflows to pick the right approach for your products. Think of these as different recipes in your warehouse's cookbook—each one is perfect for a specific situation.

The best workflow always comes down to what you're selling, how complex it is, and how quickly it moves off the shelves. When you align your kitting strategy with your product's reality, you build a much leaner, more cost-effective fulfillment machine.

Pre-Pack Kitting for Your Standard Go-To Bundles

Pre-pack kitting is the most straightforward method. It's perfect for products you frequently sell together in a fixed, unchanging bundle. The process is simple: you gather existing, ready-to-sell items and package them into a new kit, often way ahead of any customer order.

Imagine a skincare brand with a best-selling "Beginner's Trial Set." This kit always has the same three products: a small cleanser, a moisturizer, and a sunscreen. During slower periods, the warehouse team can pre-pack hundreds of these sets, slap a new master SKU on them, and stack them on the shelves. When an order for the set comes in, a picker just grabs one finished box, scans it, and it's off to shipping.

This workflow is a lifesaver for:

- Holiday Gift Sets: Curated collections of popular items dressed up for seasonal sales.

- Welcome Kits: A standard package of essentials for new subscribers or members.

- Starter Packs: A bundle of core products designed to get a customer started with a new hobby or system.

The big idea behind pre-pack kitting is locking in efficiency through preparation. By building these popular bundles ahead of time, you turn a complex, multi-item pick into a simple, single-item grab. This is how you fly through fulfillment during peak season.

Assembly Kitting for Products That Need Building

Next up is assembly kitting, which is a little more involved. This workflow is for when the final product actually needs to be constructed from individual components before it can ship. It’s less about bundling finished goods and more about creating something new from raw parts.

A flat-pack piece of furniture is the classic example. The kit includes all the wooden panels, a bag of screws and dowels, and the instruction manual. Here, the kitting process is about gathering all these separate components—which you couldn't sell on their own—into a single, complete package that’s ready for the customer to build at home.

Assembly kitting is absolutely essential for businesses that sell:

- Electronics: A DIY computer kit with a motherboard, processor, and RAM.

- Subscription Craft Boxes: A monthly box containing yarn, knitting needles, and a pattern.

- Mechanical Parts: A bicycle repair kit that includes a new chain, sprockets, and special tools.

This method demands serious precision and quality control. A single missing screw can completely derail the customer experience, so there's no room for error.

Batch Kitting When You Need to Go Big

Finally, batch kitting is all about scale. Instead of building kits one by one as orders come in, your team produces a large quantity—a "batch"—of the same kit in a single, dedicated production run. This is the go-to strategy for handling high-volume, predictable demand, like a monthly subscription box.

Think of a company that ships a monthly coffee tasting box. They know at the start of the month they need to ship 5,000 identical boxes. The fulfillment team sets up a dedicated assembly line and knocks out all 5,000 kits over just a few days. This assembly-line approach is way more efficient than trying to build each box as individual orders pop up.

This workflow is optimized for any scenario where you have predictable, high-volume orders. It lets your warehouse dedicate specific space, labor, and resources to a single task, pushing throughput to the max and crushing errors before the shipping deadline even gets close.

How Kitting Fits Into Your Supply Chain

To really get the value of kitting, you have to understand when and where it happens in your workflow. It’s not just another task for the warehouse team; it’s a strategic move that slots in right between receiving your inventory and shipping out orders. Think of it as the bridge connecting your bulk products to your customer-ready packages.

Typically, a smart fulfillment operation performs kitting right after products are received (inbound) but before they get stored away on shelves (putaway). This timing is deliberate. By building your kits at this stage, you’re turning individual components into ready-to-ship units from the get-go. What lands on your shelves is already optimized for a fast exit.

This proactive approach completely changes the game when an order comes in. Instead of a picker running around the warehouse grabbing three or four different items from different bins, they just grab one pre-assembled kit. Simple.

Kitting's Role in the Inbound to Outbound Flow

By putting the assembly work upfront, you’re smoothing out the entire path from your warehouse shelf to the customer’s doorstep. It helps you prepare for demand before it even hits, directly tackling those common fulfillment bottlenecks.

In a modern 3PL, kitting is a powerhouse for inventory management. It can slash the number of SKUs you need to track by 50-70%, turning what could be a chaotic mess of individual items into clean, organized kit zones near your packing stations. This directly fights the 37% inventory delay rate that plagues e-commerce brands, where bad tracking leads to overselling or dead stock.

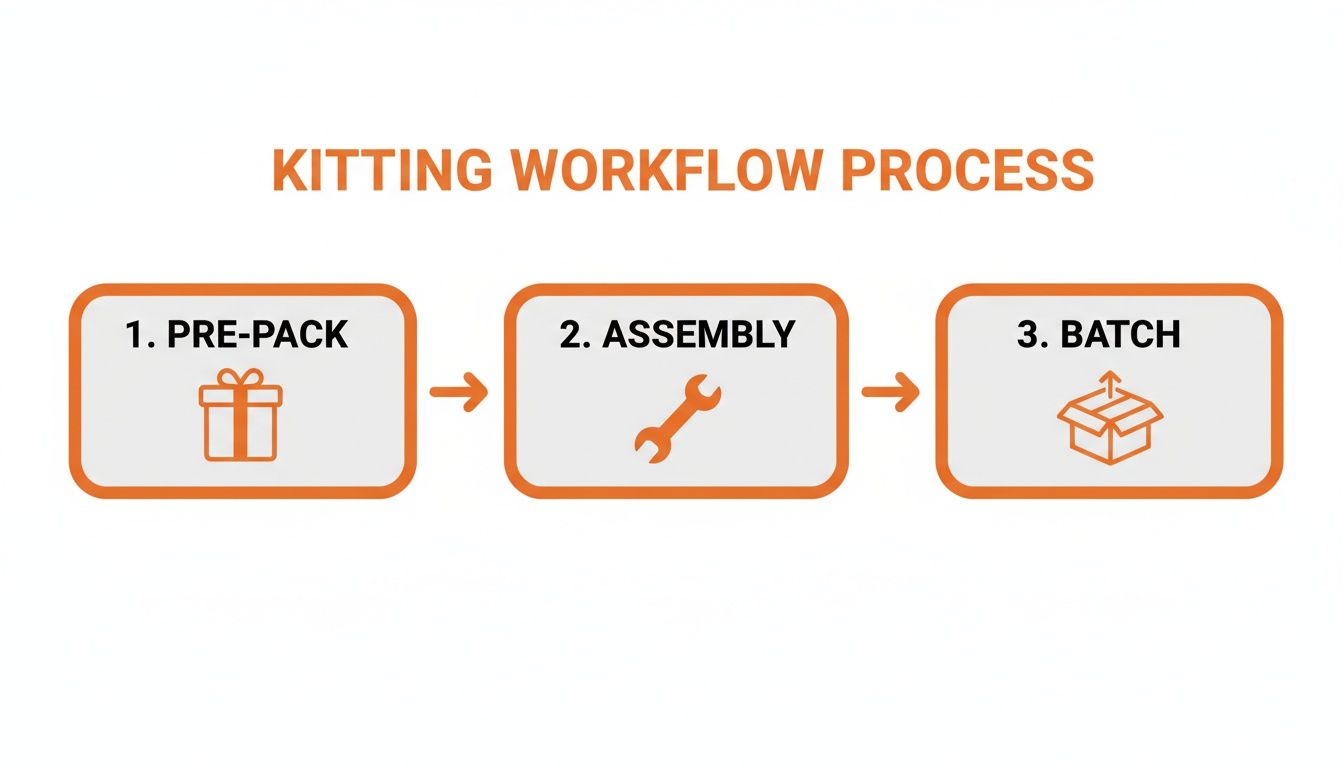

Let's look at the common kitting workflows and see how they fit into the bigger picture. The flow below shows how Pre-Pack, Assembly, and Batch kitting all happen before final storage and order fulfillment.

As you can see, it doesn't matter if you're creating gift sets, building products from components, or prepping thousands of subscription boxes. Kitting is the foundational step that gets your inventory ready for quick deployment.

To really see the difference, let’s compare a standard fulfillment process to one that uses kitting.

Traditional vs Kitting-Optimized Fulfillment Workflow

This table breaks down how much simpler and faster the outbound process becomes when kitting is done during the inbound phase.

| Fulfillment Stage | Traditional Workflow (Without Kitting) | Optimized Workflow (With Kitting) |

|---|---|---|

| Receiving | Individual components (Items A, B, C) are received and counted separately. | Individual components (Items A, B, C) are received and counted separately. |

| Kitting/Pre-Assembly | N/A – Assembly happens during the picking phase. | A dedicated team assembles Items A, B, and C into a single kit with a new SKU. |

| Putaway | Items A, B, and C are stored in separate bin locations, often far apart. | The pre-assembled kit is stored in a single, easy-to-access bin location. |

| Picking | A picker receives an order and must travel to three different locations to get A, B, & C. | A picker receives an order and goes to one location to grab the complete kit. |

| Packing | The packer verifies that all three individual items are correct before sealing the box. | The packer simply places the single kit into the shipping box. Verification is faster. |

| Order Accuracy | Higher risk of picking errors (e.g., wrong item, missing item). | Significantly lower risk of error, as the kit's contents were verified during assembly. |

The takeaway is clear: front-loading the assembly work eliminates multiple touchpoints and decision points during the high-pressure picking and packing stages, leading to faster, more accurate fulfillment.

A Critical Step for Amazon FBA Preparation

If you sell on Amazon FBA, kitting isn’t just a nice-to-have—it’s often a flat-out requirement. Amazon’s rules for how inventory must arrive at their fulfillment centers are strict and non-negotiable. Get it wrong, and you're looking at costly delays, rejected inventory, or surprise prep fees from Amazon.

Kitting is the engine behind successful FBA prep. It ensures your bundled products are perfectly packaged, labeled, and compliant before they ever reach an Amazon facility, preventing costly rejections and speeding up your inventory check-in time.

An FBA prep service that handles kitting will take care of several crucial tasks:

- Compliant Bundling: Assembling your multi-packs or product bundles so they are sold as a single unit. Each bundle must be contained within one outer package.

- FNSKU Labeling: Covering up any old manufacturer barcodes and applying Amazon's unique FNSKU label to the outside of the final kit. This is mandatory for tracking your stuff in their network.

- Creating Case Packs: Grouping multiple kits into a single master carton, which is then labeled according to Amazon’s specific case-pack guidelines.

- Adding Suffocation Warnings: Applying the required warning labels to any poly bags that have an opening of five inches or more.

By getting this detailed work done ahead of time, your products fly through Amazon’s receiving process and become available for sale that much faster. For brands that sell on multiple channels, this disciplined approach is even more essential. To learn more about how a 3PL can manage this for you, check out our guide to e-commerce order fulfillment services.

Best Practices for Successful Kitting

Getting a kitting process up and running is one thing. Turning it into a profitable, error-free engine for your business is a whole different ball game. Successful kitting comes down to precision, foresight, and a disciplined approach to both your inventory and your quality control. Think of these best practices as the guardrails that keep your kitting operations running smoothly and prevent costly mistakes.

Without them, common pitfalls like stockouts, inaccurate kits, and operational bottlenecks can easily derail your entire fulfillment strategy.

Maintain a Flawless Bill of Materials

The Bill of Materials (BOM) is the absolute source of truth for your kits. It's the exact recipe, listing every single component SKU, its required quantity, and any special packaging instructions needed to assemble one finished kit. An inaccurate BOM is the root cause of almost every kitting failure.

Even a tiny mistake—listing the wrong size screw or an outdated product version—can cascade into thousands of incorrect kits. That creates a ripple effect of unhappy customers, expensive returns, and a logistical nightmare to sort out. Your BOM has to be a living document, updated the second a component or packaging detail changes.

To keep it pristine, your team must:

- Regularly Audit the BOM: Physically compare the documented recipe against the components on the shelf. This is the best way to catch discrepancies before they become big problems.

- Implement Version Control: When a kit is updated, create a new version of the BOM instead of just overwriting the old one. This avoids mix-ups and confusion on the assembly line.

- Link it to Your WMS: A modern Warehouse Management System can pull data directly from the BOM, guaranteeing assemblers always have the most current instructions.

Implement Rigorous Quality Assurance Checks

Quality Assurance (QA) is your safety net. It’s the process that ensures every kit leaving the assembly station is 100% correct and complete. Just hoping your assemblers won't make mistakes isn't a scalable strategy. A formal QA process is non-negotiable.

This doesn't have to be overly complicated. It can be as simple as having a second person spot-check a percentage of finished kits from every batch. For more complex or high-value kits, you might use a multi-point inspection checklist for every single unit.

A strong QA process turns kitting from a potential liability into a reliable competitive advantage. It ensures the accuracy that customers expect and prevents small errors from becoming expensive, brand-damaging problems.

A solid QA workflow checks for the right components, proper placement inside the box, accurate labeling, and the overall look and feel of the final kit.

Leverage Technology for Real-Time Tracking

Trying to manage kitting with spreadsheets is a recipe for disaster once your business starts to grow. A Warehouse Management System (WMS) is essential for tracking both your individual components and the finished kits in real time.

A WMS gives you the visibility needed to make smart decisions. It tells you exactly how many kits you can build with the components you have on hand and tracks where every finished kit is located in your warehouse. This is what stops you from selling kits you can’t actually build.

Beyond that, a WMS helps streamline the physical assembly process by:

- Guiding workers with clear, on-screen instructions and visuals.

- Using barcode scanning to verify each component as it's added to the kit.

- Automatically deducting component inventory and adding finished kit inventory.

This level of automation is fundamental to scaling your kitting operations without introducing chaos. It’s the tech backbone that holds all your other best practices together.

When to Outsource Kitting to a 3PL Partner

When you’re just starting out, handling your own kitting feels like a huge win. You have total control, and it seems simple enough. But as your brand grows and orders start piling up, that once-manageable task can quickly turn into a massive operational headache.

Suddenly, kitting is tying up valuable warehouse space, pulling your team away from other critical jobs, and becoming a serious bottleneck. So, how do you know when it’s time to pass the torch to a third-party logistics (3PL) partner?

Recognizing that tipping point is everything. Outsourcing isn't just about getting a task off your plate—it's a strategic decision to unlock efficiency and growth that might be impossible to achieve on your own.

Key Triggers for Outsourcing Kitting

There are a few tell-tale signs that your kitting process is bursting at the seams. If you find yourself nodding along to more than one of these, it’s probably time to start talking to a 3PL.

Soaring Order Volumes: Is your team constantly scrambling to keep up with daily orders, let alone a holiday rush? When kitting feels like a race against the clock, outsourcing gives you the scalable labor and dedicated space to meet demand without missing a beat.

Increasing SKU Complexity: As you launch new products and create more ambitious bundles, the risk of error skyrockets. A good 3PL partner uses a powerful Warehouse Management System (WMS) and has battle-tested quality control to manage complex Bills of Materials (BOMs) without a single mistake.

Need for Specialized Services: Thinking about selling on Amazon FBA? Their prep requirements are notoriously strict and completely non-negotiable. An expert 3PL ensures your kits are bundled, labeled, and packed in full compliance, so you can avoid costly rejections and frustrating delays at the fulfillment center.

Outsourcing kitting isn't admitting defeat; it’s choosing to focus on what you do best—growing your brand. A specialized 3PL already has the infrastructure, technology, and trained personnel to execute your kitting strategy more efficiently and cost-effectively than you can in-house.

The Benefits of Partnering with a 3PL

Bringing a fulfillment pro into the mix does a lot more than just free up your schedule. It delivers real, tangible benefits that hit your bottom line and improve your customer experience.

If you're still getting familiar with the terminology, you can learn more about what a 3PL warehouse is and how it functions in our detailed guide.

A partnership delivers several key advantages:

Cost Savings: Forget about the massive upfront costs of leasing more space, buying specialized equipment, and hiring more people. A 3PL spreads these expenses across all its clients, giving you access to enterprise-level tools for a fraction of the cost.

Scalability on Demand: A 3PL can ramp up or scale down its resources to perfectly match your sales. Whether you're in a slow season or in the middle of a massive Black Friday rush, you get exactly the labor and space you need without being stuck with fixed overhead.

Expertise and Technology: Fulfillment partners live and breathe logistics. They bring years of hands-on experience and powerful WMS technology to the table, ensuring your kitting is done right, every single time.

Got Questions About Kitting? We've Got Answers.

When brands start digging into what kitting can do for them, a few practical questions always pop up. It makes sense—you need to understand how it fits into your business, from what it costs to what your customers will think. Let's clear up some of the most common ones.

Kitting vs. Bundling: What’s the Real Difference?

People use these terms interchangeably all the time, but in the logistics world, they mean two very different things.

Kitting is a warehouse operation. It’s the physical act of taking individual items, assembling them into a ready-to-ship package, and assigning that new package its own SKU. This happens before a customer ever clicks "buy." Think of it as pre-building inventory.

Product bundling, on the other hand, is all about marketing. It’s when you sell multiple items together on your storefront, usually for a single price. A bundle can be fulfilled by picking each item separately after an order comes in, or it can be fulfilled using a pre-made kit.

Simply put: Kitting is the how (the warehouse work), while bundling is the what (the sales offer).

How Do 3PLs Charge for Kitting?

When you hand over kitting to a 3PL, you’re not just paying for shelf space; you’re paying for a hands-on service. The pricing is almost always tied directly to the labor involved.

Here are the usual ways it's broken down:

- Per-Kit Fee: A simple flat rate for each kit assembled. This is perfect for straightforward kits where the assembly time is always the same.

- Hourly Rate: For more complex projects or kits that have a lot of variation, a 3PL might charge by the hour. This is common for jobs that need more delicate or detailed work.

- Per-Component Touch: Some 3PLs charge a small fee for every single item, or "touch," that goes into the kit. A kit with ten small parts will naturally cost more to assemble than one with just three.

A good 3PL partner will be transparent about how they charge. The best pricing model is one that reflects the actual work being done, giving you a predictable cost that makes sense for your products and volume.

Can Kitting Really Improve the Unboxing Experience?

Absolutely. This is one of the biggest wins of kitting. It gives you total control over how your products show up at your customer's door, which is a huge deal in e-commerce today.

Instead of your customer getting a box with a bunch of loose items rattling around, they receive a thoughtfully arranged, professional-looking package.

You can design custom inserts, make sure products are presented in a specific order, and create a premium, intentional feel. A great unboxing experience isn't just about looking good—it builds your brand's value, gets people excited to share on social media, and makes customers feel like they bought something truly special. It turns a delivery into a memorable moment.

Ready to stop worrying about logistics and start scaling your business? Snappycrate offers expert kitting, fulfillment, and FBA prep services designed for growth-minded e-commerce brands. Discover how we can streamline your operations at https://www.snappycrate.com.