When you hear "kitting and assembly," you might picture a factory floor, but for e-commerce sellers, it’s a powerhouse strategy that happens right in the fulfillment center. At its core, it's about taking individual items and grouping them together to be sold as a single unit. This simple act turns a pile of separate products into one ready-to-ship bundle, like a curated skincare gift set or a monthly subscription box.

The real magic is how this simplifies your backend operations and speeds up the entire fulfillment process.

Unpacking Kitting and Assembly Services

Think of kitting like a meal-prep service for your products. Instead of a customer (or your warehouse team) having to pick out a tomato, an onion, and a packet of spices individually, your fulfillment partner acts as the chef. They gather everything needed for the "recipe" ahead of time and package it into one convenient box.

This has a massive impact on your inventory. It takes multiple individual SKUs (Stock Keeping Units) and transforms them into one new, easy-to-manage master SKU. For anyone selling on platforms like Amazon, Shopify, or Walmart, this is a total game-changer. Instead of your pickers hunting down five different items for a holiday gift set, they just grab one pre-made box. This cuts down on labor, virtually eliminates picking errors, and gets orders flying out the door.

It's no surprise the demand for these services is exploding. The global market for kitting and assembly has skyrocketed from USD 8.4 billion and is projected to hit USD 17.0 billion by 2034. This boom is driven by brands just like yours, looking to create special promotions, subscription boxes, and value-added multi-packs. You can learn more about these kitting market growth projections and see what's fueling the trend.

Kitting vs. Assembly: What’s the Real Difference?

The terms "kitting" and "assembly" are often thrown around together, but they’re two distinct processes. Nailing down the difference is critical when you’re talking to a fulfillment partner, as it defines the entire scope of your project.

Simply put: kitting is about grouping, while assembly is about building.

Let’s break it down further. The table below gives a quick side-by-side look at how these two services differ in practice.

Kitting vs Assembly At a Glance

| Aspect | Kitting Services | Assembly Services |

|---|---|---|

| Core Function | Grouping separate, finished items into a single package. | Combining multiple parts to create a new, single product. |

| Product State | Individual items remain unchanged. | Individual parts are altered or combined; light manufacturing. |

| Example | A "Welcome Kit" with a water bottle, towel, and keychain. | Screwing together parts of a chair before boxing it. |

| Complexity | Lower; primarily a pick-and-pack process. | Higher; requires instructions, tools, and quality checks. |

| Labor Skill | Basic warehouse skills. | Requires training and sometimes specialized tools. |

As you can see, kitting is more about curation, while assembly is about creation. One gathers existing items, and the other builds a new one from scratch.

Here's an easy way to remember it: Kitting creates a collection of items. Assembly creates a single, new item from multiple parts.

In many fulfillment projects, these two services actually go hand-in-hand. A 3PL might first perform assembly—like putting together an electronic device—and then kit it with accessories like a charger and manual before creating the final retail-ready package.

The key takeaway is that both services streamline your operations by doing the heavy lifting before a customer ever clicks "buy."

Strategic Benefits of Outsourcing Kitting to a 3PL

Partnering with a third-party logistics (3PL) provider for your kitting and assembly services does way more than just free up your time—it’s a strategic move that directly boosts your bottom line, protects your brand, and lets you grow. Trying to manage kitting in-house might feel like you have more control, but it often brings a ton of hidden costs and operational headaches that can actually hold you back.

When you outsource, you turn a complex, often messy process into a smooth, efficient engine for your business. It lets you swap fixed costs, like warehouse rent and employee salaries, for variable costs that scale up or down with your sales. That kind of financial flexibility is a game-changer, especially for brands with seasonal peaks or those growing like crazy.

Driving Down Operational Costs

One of the first things you'll notice is a serious drop in your expenses. When you handle kitting yourself, you’re not just paying for labor. You're also on the hook for dedicated workspace, packing supplies, costly mistakes, and the lost opportunity of what your team could be doing instead. A 3PL just absorbs all of that.

A specialized fulfillment partner operates at a massive scale, which means they get better prices on things like boxes and packing materials—savings they can pass right on to you. It's a proven fact that direct-to-consumer (DTC) brands can see cost savings of 20-25% on labor and materials alone by outsourcing kitting. For sellers on tough marketplaces like Amazon and Shopify, that financial edge can be the difference between thriving and just getting by.

Enhancing Order Accuracy and Customer Experience

Fulfillment mistakes are expensive. Sending a customer a kit with the wrong item doesn't just mean a costly return; it chips away at the trust you've built with them. A single bad review can scare off countless future customers. Professional 3PLs, on the other hand, build their entire business on getting it right.

They use multi-step verification, like barcode scanning and weight checks, at every single point on the assembly line. This systematic approach pretty much eliminates human error.

By outsourcing, you’re not just handing off a task—you’re investing in a system built for near-perfect accuracy. This precision means the awesome unboxing experience you designed is the one your customer actually gets, every single time.

This focus on quality is also critical for staying compliant with marketplaces. For Amazon FBA sellers, a bad kitting job can get your inbound shipments rejected, a problem that hits an estimated 15-20% of shipments from sellers who aren't prepared. A good 3PL knows Amazon's strict rules inside and out—from FNSKU labeling to poly bagging—so your inventory gets checked in smoothly without any penalties. If you want to get a better handle on what a fulfillment partner does, our guide on what a 3PL warehouse does is a great place to start.

Unlocking Scalability and Business Focus

Picture this: you launch a new subscription box or a huge holiday sale. Can your current setup handle a sudden jump from 100 orders a day to 1,000? For most brands, that kind of spike would cause total chaos, shipping delays, and a lot of unhappy customers.

This is where a 3PL partner becomes your secret weapon for growth. They already have the warehouse space, technology, and trained staff to handle massive swings in order volume without breaking a sweat.

Here’s how a 3PL helps you scale:

- Elastic Workforce: They can throw more staff at your project during peak season and scale back when things quiet down.

- Optimized Space: You get access to a massive warehouse without signing a long-term lease, and you only pay for the space you actually use.

- Expert Processes: They’ve already perfected workflows for high-volume kitting and assembly services, so there’s no learning curve.

By handing off all these logistical headaches, you and your team can finally stop packing boxes and get back to what you're best at: creating amazing products, marketing your brand, and talking to your customers. That shift in focus is the real strategic advantage.

A Look Inside the Kitting and Assembly Workflow

Ever wonder what actually happens when you hand off a kitting project to a 3PL? It’s not just a matter of tossing items into a box. It's a finely tuned process built for speed and, most importantly, accuracy.

Getting a peek behind the curtain helps you understand where the real value is created. Let's walk through the entire journey, from creating your kit’s “recipe” to getting it stocked and ready to ship at a moment's notice.

Step 1: Defining the Project Scope

Everything starts with a detailed consultation. Think of this as you and your 3PL partner acting as architects, drawing up the exact blueprint for your finished kit. You’ll define the bill of materials—a precise list of every single component SKU that goes into the final product.

This isn’t just a simple checklist; it's a complete set of instructions. You’ll specify everything from how items should be placed inside the box to where to put that marketing insert or special sticker. The goal is to create a crystal-clear, repeatable process that guarantees every single kit looks and feels identical.

Step 2: Receiving and Inspecting Components

Once the plan is locked in, your 3PL is ready to receive all the individual parts at their warehouse. As items arrive, each one is carefully inspected to make sure it matches the specs and hasn't been damaged in transit. This initial quality check is absolutely critical.

A single scuffed item can ruin the unboxing experience, and catching these issues upfront saves you from major headaches and costs later on. Every component is counted and its SKU is logged into the Warehouse Management System (WMS), giving you total inventory visibility from day one.

Step 3: Workstation Setup and Assembly

With all the components checked in and ready, the 3PL sets up a dedicated assembly line. Picture a professional kitchen, where every ingredient and tool is perfectly placed to make the workflow as efficient as possible. These stations are designed to minimize wasted movement and shave precious seconds off each kit's build time.

Then, the assembly begins. Trained staff follow the blueprint from step one to the letter. Every action is standardized, from folding the box just right to applying the final sealing tape. For Amazon sellers, this is also the moment when crucial FNSKU labels are applied—a step that demands total precision to avoid frustrating FBA check-in problems. You can learn more about these strict guidelines in our guide to Amazon FBA labeling requirements.

Step 4: Quality Control and SKU Creation

Throughout the assembly process, there are multiple quality control checkpoints. Supervisors will spot-check kits, while tools like barcode scanners and digital scales can instantly verify that each kit contains the correct items and weighs exactly what it should. This layered approach is how high accuracy rates are maintained.

After a kit is fully assembled and passes its final inspection, it's assigned a brand new, single master SKU. This new SKU is created in the WMS, officially turning a pile of separate parts into one unified, sellable product.

This master SKU is the key to simplifying your inventory. Instead of tracking five different components for a gift set, your ecommerce platform now only needs to track one—the finished kit.

Step 5: Storage and Fulfillment Readiness

The last step is to move the completed kits to their designated storage spot in the warehouse. They're no longer treated as individual parts but as finished goods, ready for immediate picking. So, when a customer orders that kit from your Shopify or Walmart store, there's no frantic scramble to find and pick multiple items.

Your fulfillment team just picks one box with the master SKU, packs it for shipping, and sends it on its way. This is how you drastically cut down on order processing time.

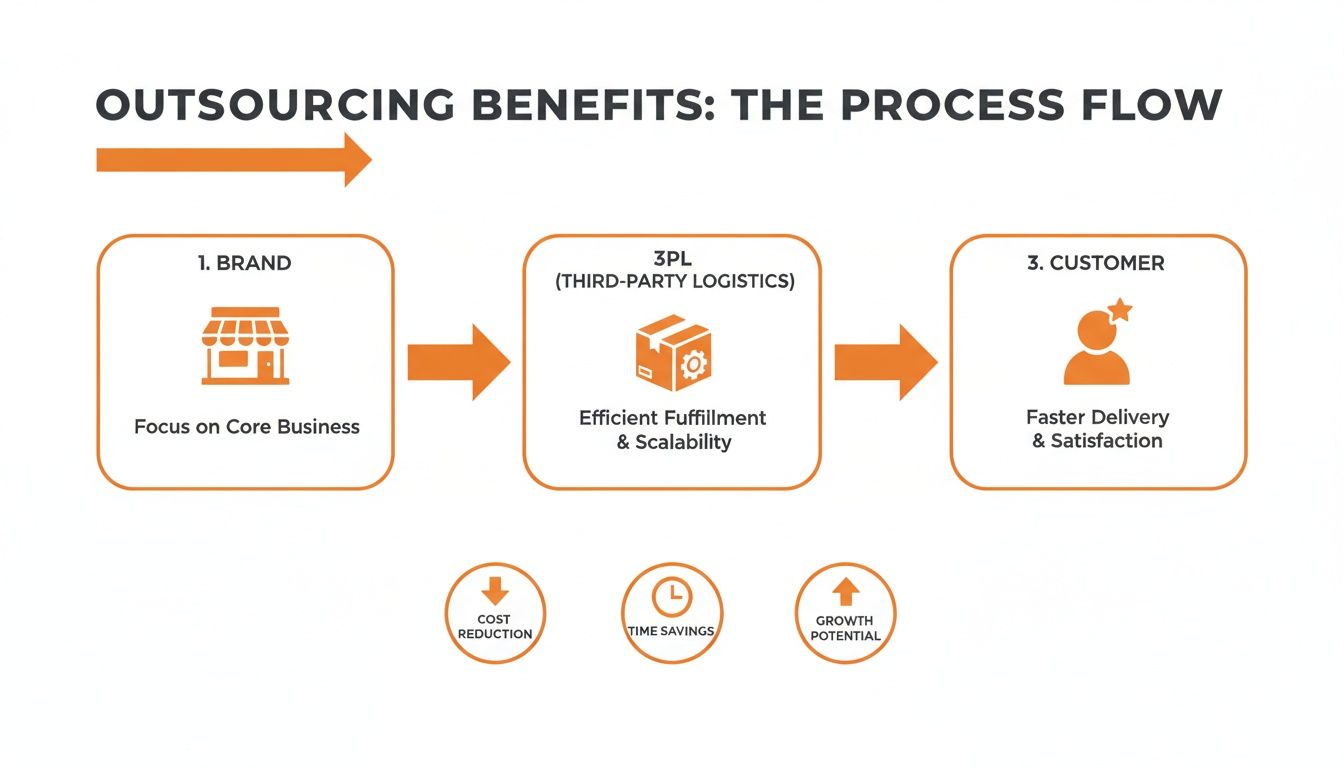

This visual shows how outsourcing connects your brand, your fulfillment partner, and your end customer into a seamless operation.

This workflow turns what could be a chaotic internal project into a predictable, scalable, and highly accurate operation run by pros.

How Technology is Actually Changing Modern Kitting

If you think kitting and assembly is still just about people carefully packing boxes by hand, you’re missing the bigger picture. The entire process has been overhauled by technology, turning it into a high-precision, data-driven operation.

For e-commerce sellers and ops leaders, this shift is a game-changer. It’s the difference between hoping your orders are right and knowing they are. Modern 3PLs now deliver a level of speed, accuracy, and transparency that was simply impossible a decade ago. It means you get more than just bundled products—you get a fulfillment partner you can actually rely on.

The Warehouse Management System: Your Kitting Command Center

At the core of any tech-forward fulfillment center is its Warehouse Management System (WMS). Think of it as the brain of the entire kitting operation. It’s not just counting inventory; it's orchestrating every single step with digital precision.

This system is your single source of truth. It knows exactly how many screws, widgets, and instruction manuals you have in stock. It knows how many finished kits are ready to ship. And it knows which components are currently being assembled into new kits. That level of detail is non-negotiable for running a smooth operation.

A solid WMS lets a 3PL:

- Keep Inventory Separate: It digitally tags your raw component SKUs and your finished, ready-to-sell master SKUs. No more accidental shipments of loose parts.

- Give You Real-Time Updates: You can log into a portal anytime and see exactly what’s happening with your inventory. This is huge for making smart forecasting and purchasing decisions.

- Set Automatic Reorder Points: The system can ping you when a specific component is running low, so a single missing part doesn’t bring your entire production to a halt.

This digital oversight takes the guesswork out of inventory management, ensuring the parts for your kitting and assembly services are always on hand when you need them.

Barcode Scanning: The Simple Fix for Human Error

Let’s be honest—human error is the biggest killer of kitting accuracy. A warehouse picker grabs the blue shirt instead of the black one, and suddenly you’re dealing with an unhappy customer and a costly return. This is where barcode scanning becomes your best friend. It’s a simple, foolproof check at every single step.

When your components first arrive at the warehouse, they’re scanned into the WMS. During assembly, each item is scanned again to confirm it matches the kit’s “recipe.” This forces a digital handshake, catching mistakes before they ever get inside a box.

By integrating barcode scanning, a 3PL can all but eliminate picking errors. It’s a simple but incredibly powerful layer of quality control that guarantees what you designed is what your customer actually gets.

Automation and Robotics: Kitting at Scale

The next big leap is automation. Robots and other automated systems are now handling the repetitive tasks, allowing 3PLs to scale up to massive volumes without compromising on quality. And this isn't just for massive corporations anymore—it’s becoming a must-have for successful e-commerce brands dealing with high order volumes.

Automation is already making a huge impact. The global market for kitting automation is valued at USD 2.10 billion and is projected to hit USD 7.15 billion by 2033. In North America, advanced robotics are cutting picking errors by 50% and boosting how many orders can get out the door. For high-volume sellers, this translates to a 15-30% drop in operational costs while hitting 99%+ accuracy. You can dive deeper into how automation is reshaping the kitting industry on snsinsider.com.

When you combine a powerful WMS, mandatory scanning, and smart automation, a modern 3PL truly becomes an extension of your business—one that’s built to be reliable, transparent, and ready to handle your growth.

Finding the Right Kitting and Assembly Partner

Picking a 3PL partner is one of the biggest calls you’ll make for your e-commerce brand. This isn’t just about renting warehouse space or finding someone to slap a label on a box. It’s about trusting another company with your inventory and, ultimately, your customer's happiness.

A great partner feels like an extension of your own team, proactively solving problems and helping you scale. The wrong one? They become a source of constant headaches, creating costly bottlenecks and damaging the reputation you’ve worked so hard to build.

Evaluating Core Competencies and Experience

Let's be clear: not all 3PLs are created equal, especially when it comes to the detailed work of kitting and assembly services. A warehouse that's great at basic pick-and-pack for simple t-shirt orders might completely fall apart when faced with a complex subscription box with ten different components.

Your first job is to find out if they have real, hands-on experience with businesses like yours. Do they live and breathe the strict compliance rules for Amazon FBA, or is their sweet spot direct-to-consumer fulfillment for Shopify brands? Deep experience with your primary sales channels is non-negotiable. A 3PL that already knows FBA prep inside and out will save you from the painful—and expensive—reality of rejected inbound shipments.

Don't just take their word for it. Ask for case studies or, even better, a few client references who sell similar products and have a comparable order volume. This is how you get undeniable proof of their skills.

Key Questions for Potential Partners

The best way to cut through the slick sales pitch is to come prepared with sharp, specific questions. Vague, hand-wavy answers are a major red flag. You want a partner who can confidently walk you through their exact processes, step-by-step.

Here are a few essential questions to get the conversation started:

- Technology and Inventory: "Show me how your WMS tracks component parts versus finished kits. Can I see a live demo of your client portal and how I can view my stock levels for both?"

- Quality Control: "Walk me through your QC process for a typical kitting project. What happens when your team finds a damaged component? What’s the communication process back to me?"

- Scalability: "Tell me about a time you handled a sudden, massive spike in kitting volume for a client during a promotion. How did your team manage it, and what was the outcome?"

- Billing and Transparency: "Can you provide a sample invoice for a kitting project? I want to see every potential line item and fee so there are no surprises."

How they answer these questions tells you everything you need to know about their operational maturity and their commitment to transparency. A great partner will welcome this level of detail.

A 3PL’s ability to clearly articulate their quality control and inventory management procedures is a direct indicator of their operational maturity. If they can't explain it simply, they likely can't execute it reliably.

A Quick Checklist for Vetting Partners

To keep your evaluation process organized, it helps to use a checklist. This ensures you're comparing each potential 3PL using the same objective criteria, making the final decision much clearer.

Use this checklist to systematically compare potential kitting and assembly partners on the factors that matter most for your business.

3PL Partner Evaluation Checklist

| Evaluation Criteria | Key Questions to Ask | Ideal Answer/Capability |

|---|---|---|

| Relevant Experience | "Can you share case studies or references from clients in my industry (e.g., subscription boxes, cosmetics, supplements)?" | Demonstrates a portfolio of successful clients with similar needs and compliance requirements (e.g., FBA, Walmart). |

| Technology & WMS | "How does your system manage component vs. finished kit inventory? Can I see real-time levels? Does it integrate with my platforms?" | The WMS provides real-time, segregated visibility. Offers seamless integrations with Shopify, Amazon, etc. |

| Quality Control | "What is your documented process for QA checks during assembly? How are errors tracked and corrected?" | Has a multi-step, documented QC process with clear protocols for handling damaged items and reporting errors. |

| Scalability | "How do you handle sudden volume spikes? Do you have dedicated kitting lines or cross-trained staff?" | Has a proven plan for flexing labor and resources to meet demand without sacrificing quality or speed. |

| Pricing Transparency | "Can I see a full fee schedule, including receiving, storage, assembly, and outbound shipping? Are there hidden fees?" | Provides a clear, all-inclusive quote with no vague "miscellaneous" charges. Explains all potential costs upfront. |

| Communication | "Who will be my dedicated point of contact? What are your standard response times for support inquiries?" | Offers a dedicated account manager and a clear Service Level Agreement (SLA) for communication. |

Treat this process like you're hiring a key employee, because you are. A thorough vetting process now prevents massive operational fires later.

Finalizing Your Decision

Once you’ve narrowed it down to a few top contenders, the final choice comes down to a balance of cost, capability, and culture. While it’s tempting to go with the lowest price, the cheapest 3PL is almost never the best value. A partner who invests in solid technology and bulletproof quality control might have a slightly higher per-kit fee, but they’ll save you thousands in the long run by preventing costly errors.

For brands with big growth plans, it's also smart to look at a provider's full range of e-commerce order fulfillment services to understand their long-term potential. Can they handle your freight, returns, and FBA replenishment down the road?

Ultimately, you need to feel confident that the 3PL truly gets your brand and has a clear plan to help you hit your goals. This decision isn't just a line item on your P&L; it's a long-term investment in your brand’s operational backbone.

Common Kitting Use Cases for Ecommerce Brands

The real power of kitting and assembly services clicks when you see how smart ecommerce brands put them to work. This isn’t just some back-end operational task; it's a core strategy for driving sales, making customers happier, and taming logistical headaches.

From subscription boxes to Black Friday promotions, kitting gives brands a framework to create unique product offers that would be an absolute nightmare to manage in-house. Let’s walk through a few common scenarios where this strategy really delivers.

The Subscription Box Model

Subscription box companies are built on one thing: delivering a fresh, curated experience month after month. The problem? The contents are always changing, which means you're constantly juggling dozens of different items for every single shipment cycle.

A 3PL partner cuts right through that chaos. Each month is a new kitting project. They receive all the different products, follow that month's specific "recipe" to assemble the boxes, and get them ready for a massive, coordinated shipment. It turns a messy, unpredictable process into a smooth, repeatable workflow.

Boosting Sales with Bundles and Multi-Packs

If you're selling on a competitive marketplace like Amazon, bumping up your average order value (AOV) is the name of the game. Kitting is the perfect play here. Instead of just selling one bottle of shampoo, you can create a bundled "Hair Care Kit" with shampoo, conditioner, and a styling cream.

This one move accomplishes several goals at once:

- Higher AOV: Customers spend more in one go.

- Increased Sell-Through: It’s a great way to move slower-selling items by pairing them with your bestsellers.

- Simplified Listings: One product page is much easier for a customer to navigate and buy than three separate ones.

Your fulfillment partner can crank out these multi-packs, apply the right FNSKU labels for FBA, and make sure every bundle meets Amazon’s strict packaging rules. This saves you from the pain of costly rejections at the fulfillment center.

By bundling products, you transform individual items into a high-value solution. The customer gets a convenient package, and you get a healthier bottom line with a stronger competitive position on the marketplace.

Creating Memorable Holiday and Gift Sets

Seasonal sales events are a huge opportunity for ecommerce brands. A beautifully packaged gift set can become a massive revenue driver, but trying to assemble thousands of them in-house during your busiest season is a recipe for disaster. This is a classic use case for outsourced kitting and assembly services.

Picture a beauty brand launching a special holiday gift box. They ship their custom-branded boxes, tissue paper, and products to their 3PL. The fulfillment team then carefully assembles each gift set exactly to the brand’s specs, creating that premium unboxing experience that customers love and rave about in reviews. By outsourcing, the brand can focus on marketing the big promotion instead of getting buried in packing tape and crinkle paper.

Kitting Services: Your Questions Answered

Even after getting the big picture, you probably still have questions about how kitting and assembly services actually work day-to-day. We get it. Here are the most common questions we hear from ecommerce brands just like yours.

What's the Real Cost of Kitting Services?

Kitting is almost always priced on a simple, per-kit basis. The fee depends on a few things: how many items go into each kit, how tricky the assembly is, and the total number of kits you need.

Sure, it’s a line item on your invoice, but it's often a fraction of the cost of doing it yourself. Once you add up your team's labor, the warehouse space you're using, all the packing materials, and the steep cost of a single fulfillment mistake, outsourcing starts to look like a bargain.

How Will Kitting Mess With My Inventory Management?

It actually does the opposite—it makes it way simpler. Your 3PL partner handles tracking all the individual component SKUs as they arrive and get assembled. Once a kit is built, it gets a brand new "master" SKU in their system.

What does this mean for you? Your ecommerce store, whether it’s on Shopify or Amazon, only has to track one final, sellable product. This single SKU dramatically cuts down on picking errors, makes sales forecasting easier, and gives you a much clearer, real-time view of your ready-to-ship stock.

Can a 3PL Use My Custom Branded Packaging?

Absolutely. This is one of the best parts of working with a pro 3PL—they bring your unboxing experience to life. You just send them your custom boxes, branded tissue paper, logo stickers, or any little marketing cards you want to include.

The kitting team will follow your directions to a T, making sure every single package looks exactly how you envisioned it. It's a small touch that goes a long way in building brand loyalty and getting those five-star reviews.

What Are the Minimum Order Quantities for Kitting?

This really varies from one 3PL to another. Some of the giant logistics companies are built for enterprise-level clients and have pretty high minimum order quantities (MOQs).

But plenty of others, like us, are set up to help growing ecommerce brands. A good partner will be flexible enough to handle a small test run for a new product launch and then easily scale up with you as your orders start pouring in.

Ready to stop worrying about logistics and start scaling your brand? Snappycrate offers expert kitting and assembly services designed for growth-minded sellers. Let us handle the details so you can focus on your business. Learn more and get a quote from SnappyCrate.